Aircraft Enclosures

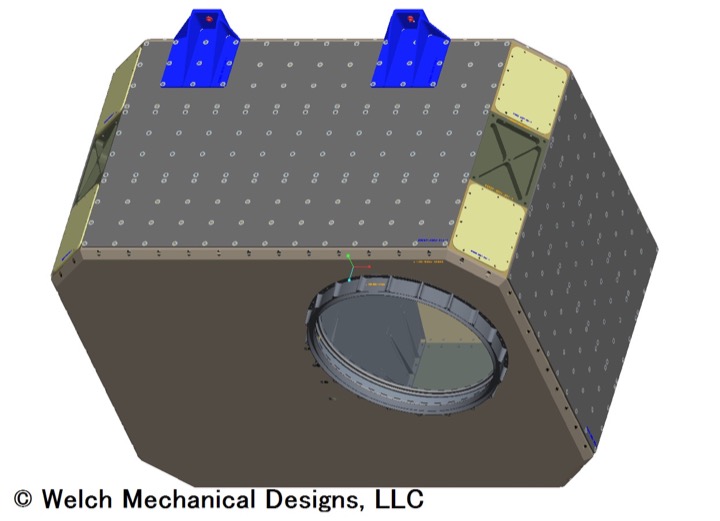

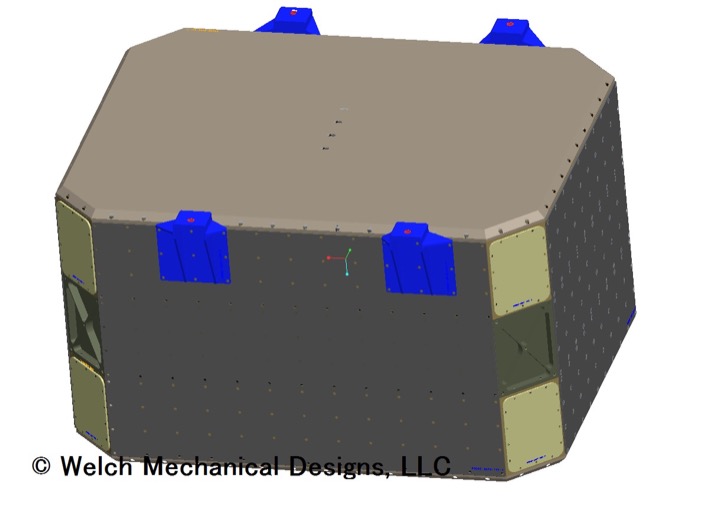

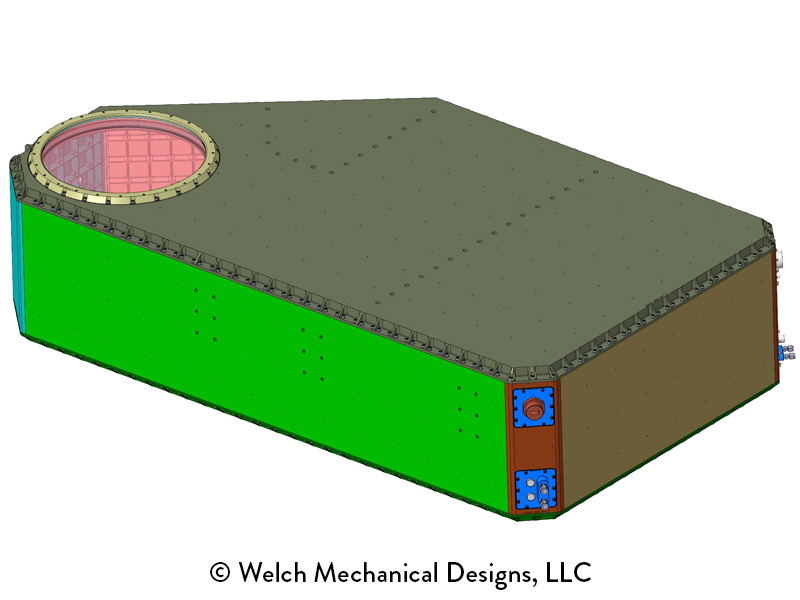

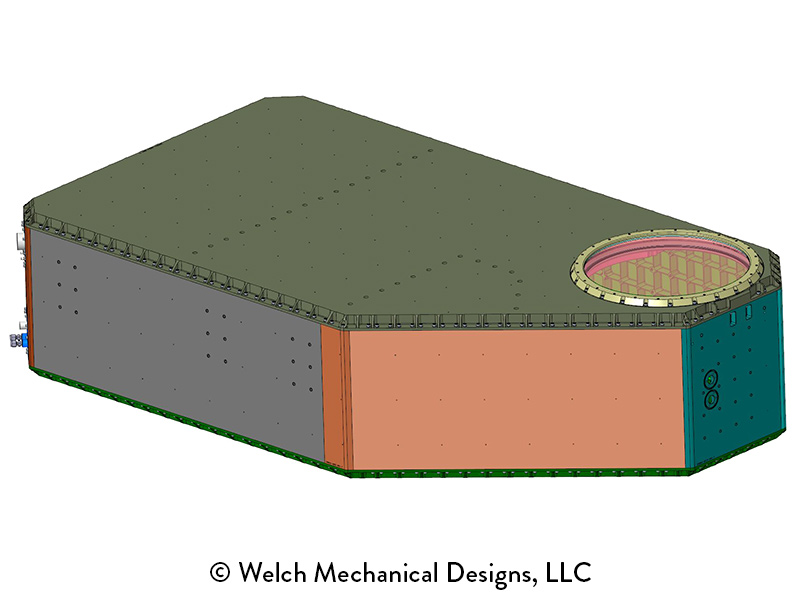

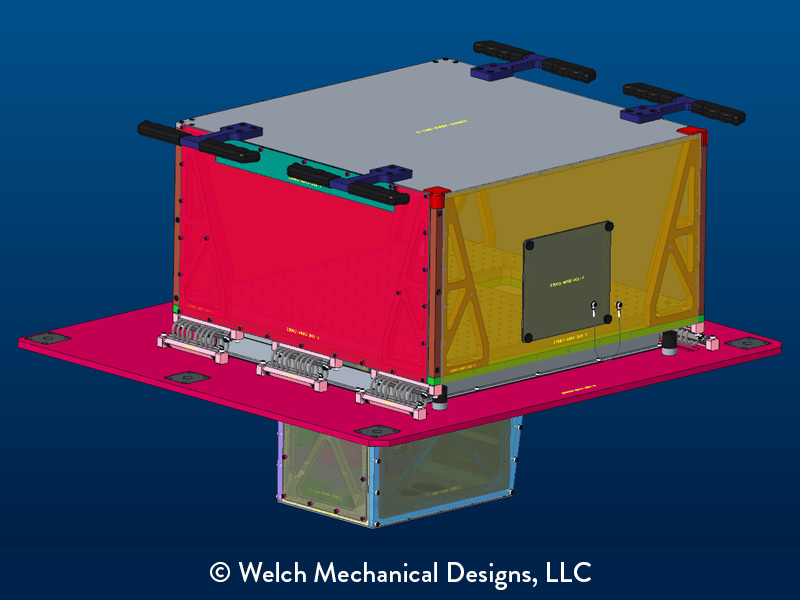

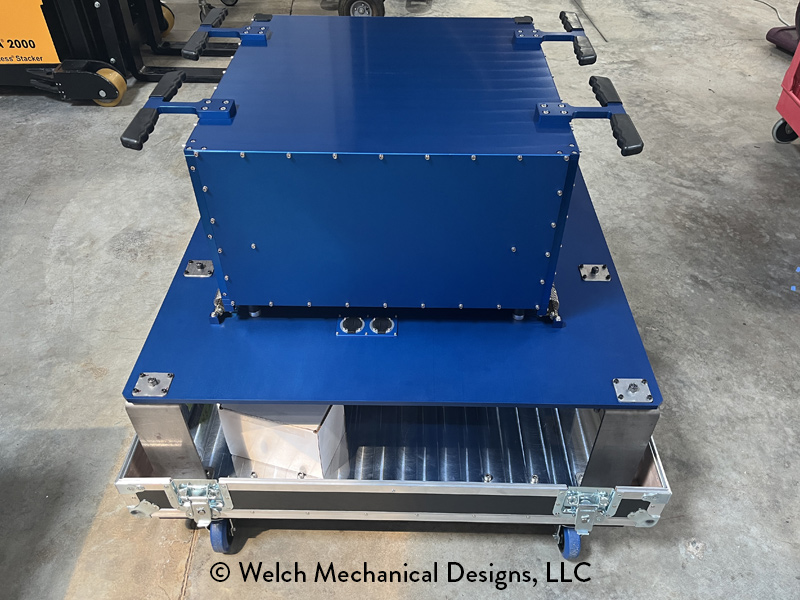

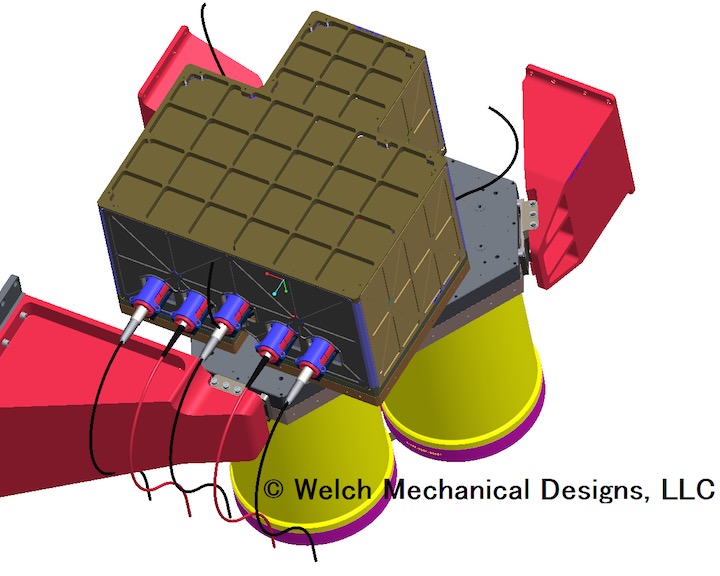

ASCENDS CarbonHawk Experiment Simulator (ACES) Environmental Enclosure

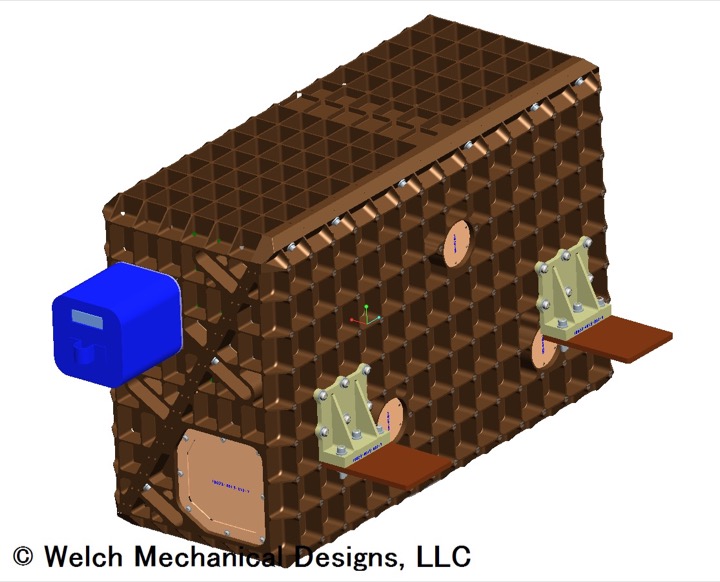

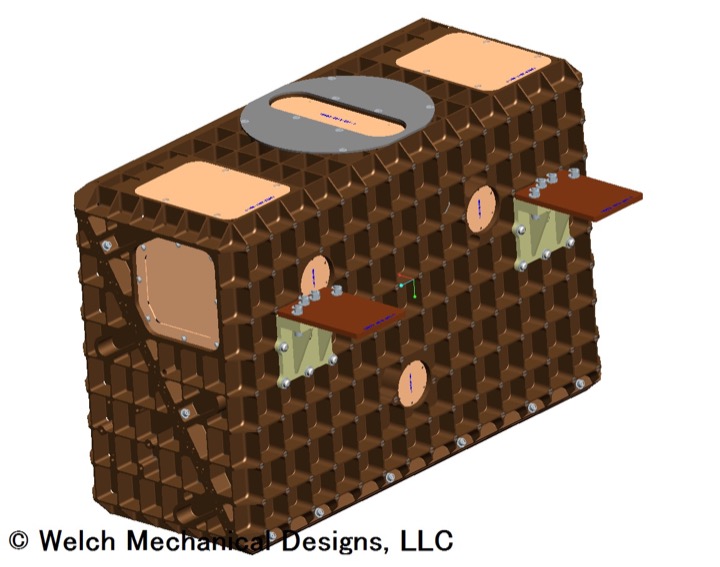

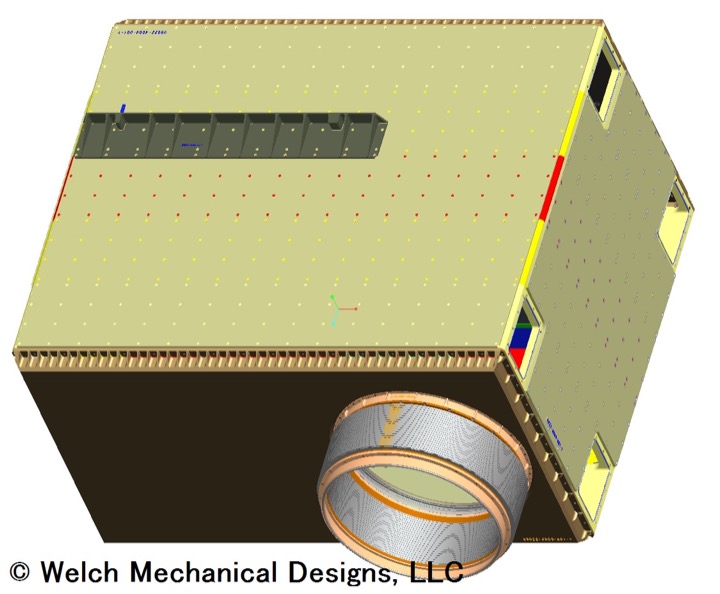

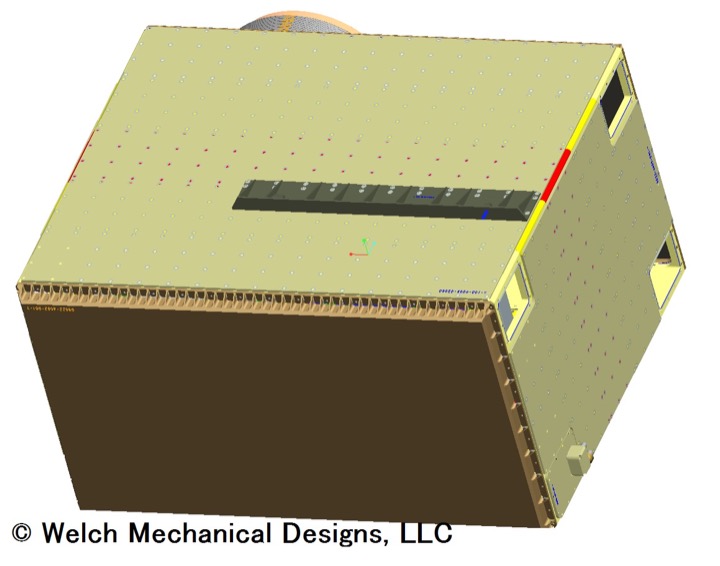

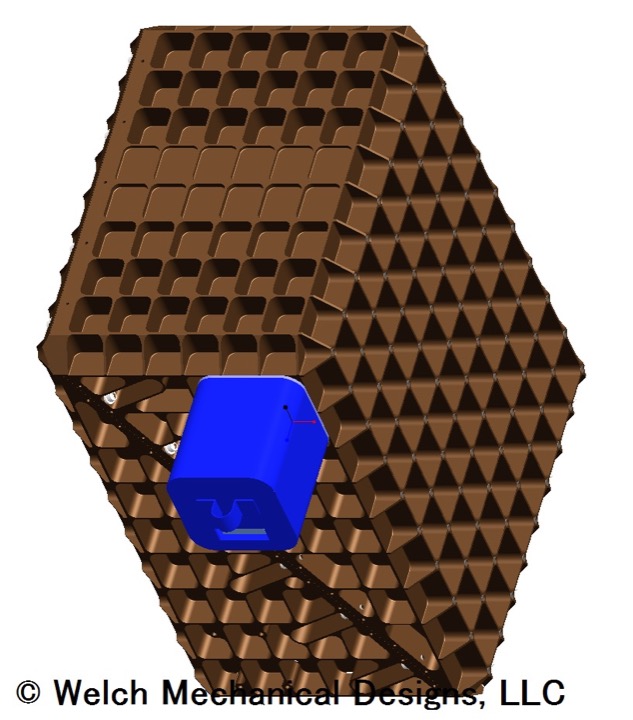

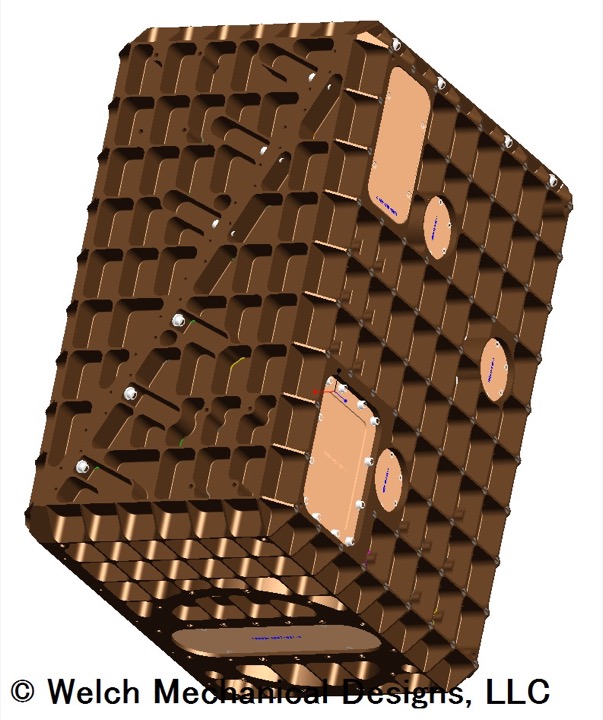

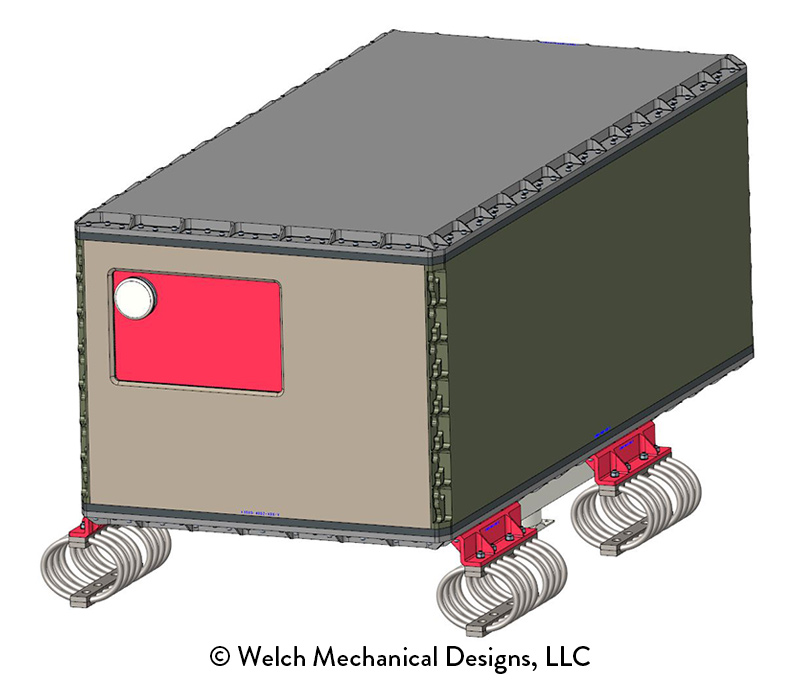

The ACES Environmental Enclosure was originally designed for the Global Ozone LiDAR Demonstrator (GOLD) but was then adapted for use in the ACES project. The current configuration is for use in the Global Hawk aircraft.

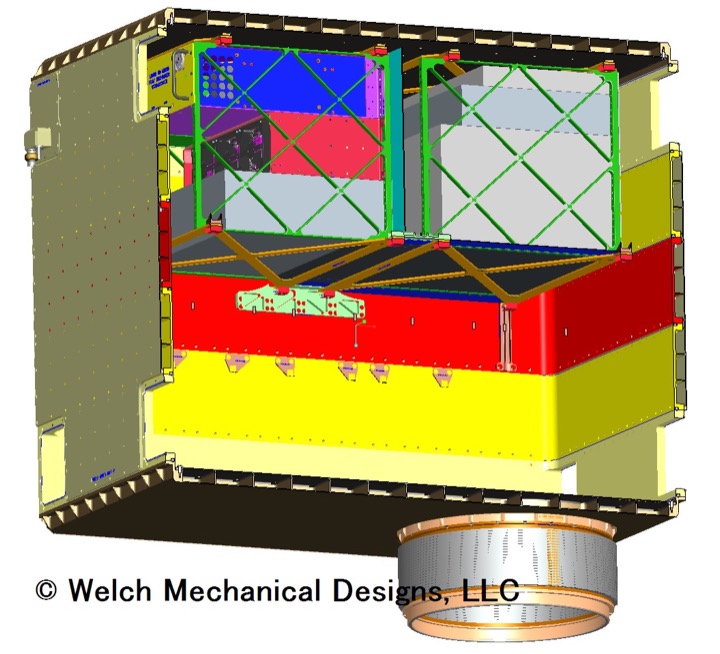

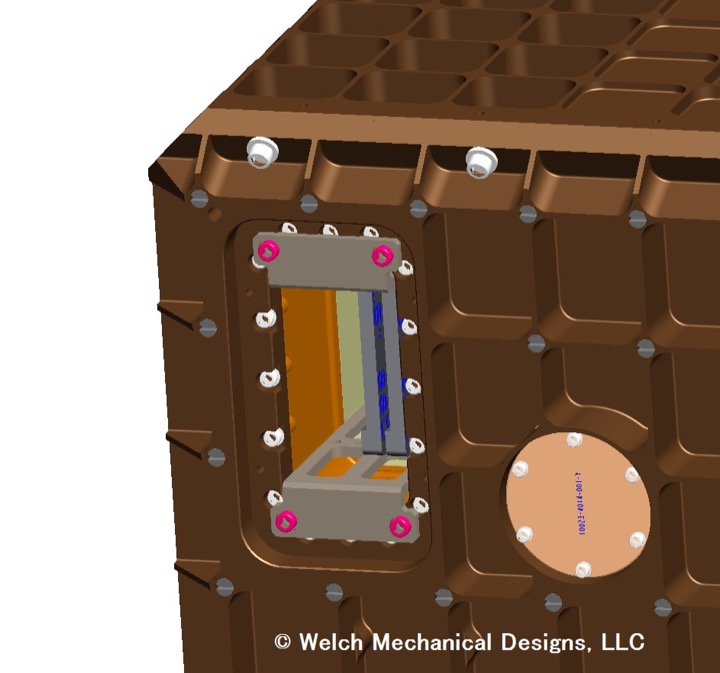

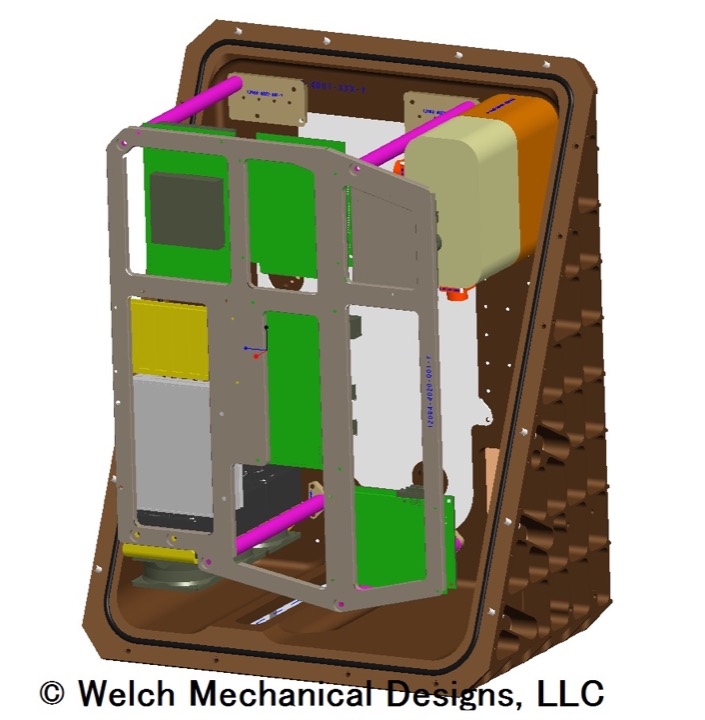

This enclosure is designed to maintain air pressure at altitude and house the ACES instrument and its supporting components in a stable environment. The design is adaptable in that there are hundreds of tapped holes with helical coils for mounting various components around the inside walls. The enclosure also includes a 17-inch (43.2-cm) wedged window, eight removable feed-through panels and a unique center shear panel.

Because of the large size of this enclosure, 34 inches (86.4 cm) X 44 inches (111.8 cm) X 25 inches (63.5 cm), the components were extensively pocketed to save weight. In order to maintain strength, WMD used a novel technique for creating a closed-cell structure rather than open pockets. The result is significantly stronger for the same total mass. An extensive FEA was also performed to aid in keeping the weight down while maintaining structural stability. As an example of the weight savings, the mass of the solid stock for the main enclosure was 3,650 lbs (1656 kg), and the final weight of the same finish-machined parts is just 181 lbs (82 kg).

All joints and openings are sealed using o-rings, and all assembly holes contain helical coil inserts.

The enclosure can be mounted in several types of aircraft by adding different custom adapter brackets. With so many mounting points on the exterior, custom brackets are easily designed and incorporated.

All of the required and desired design elements were incorporated into the design shown in the renderings.

Challenges:

One of the challenges on this project is the large number of tapped holes in the design that must align with precision diameter clearance holes in the shear panels. To overcome this obstacle, WMD developed a process to keep matching holes aligned and ensure proper assembly.

Another challenge was the pocketing required to reduce weight. This pocketing required extensive custom machining fixtures but we completed the parts on schedule, with no extra scrapped parts during the process. This is a testament to our quality and the ability to get it right the first time.

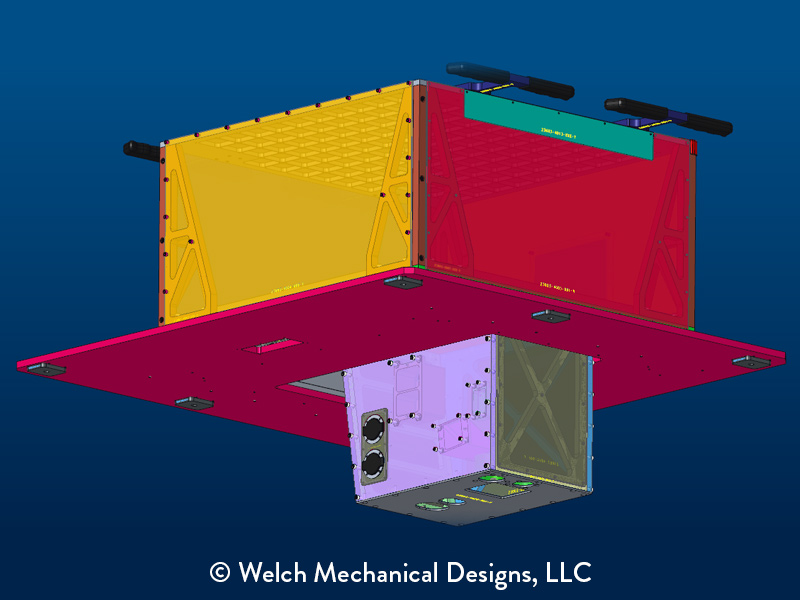

Enhanced MODIS Airborne Simulator (EMAS) Environmental Enclosure

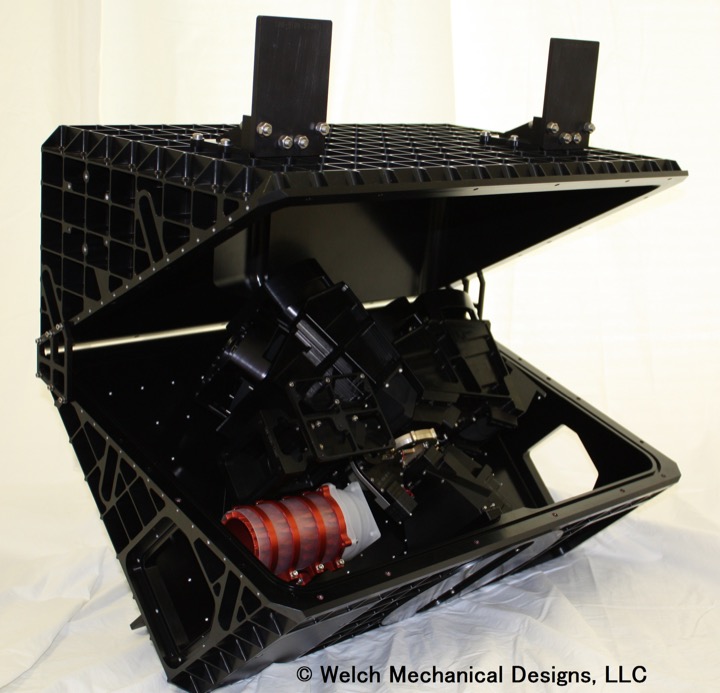

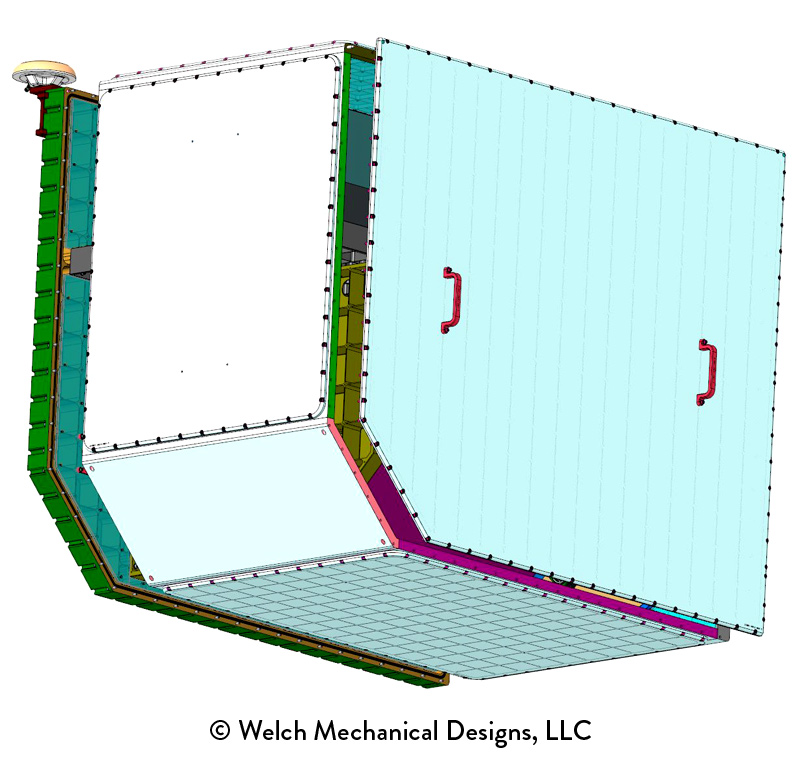

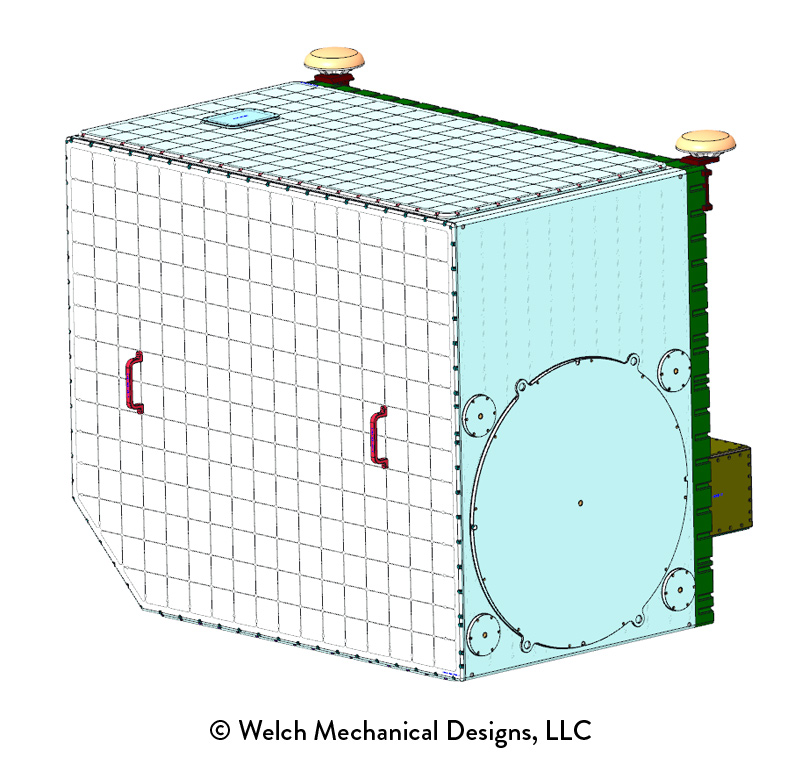

The EMAS environmental enclosure was a new type of enclosure design for us. Since it houses a smaller instrument than most of our other enclosure designs, we were able to use a clam-shell design that reduces the number of sealed joints while allowing better instrument access. This enclosure includes the two clam-shell halves sealed with an o-ring, a specially designed electronics support rack, two feed-through panels, a heating system for maintaining temperature at altitude, a unique oval-shaped window and two integrated external hard drive bays that house up to four solid state drives. The EMAS enclosure is deployed in NASA's ER-2 high altitude research aircraft.

Challenges:

The need for extensive external pocketing of the clam-shell halves led us to create a new FEA process that allows for fast optimization during design.

Another challenge was the desire to have removable external SSD storage for the data collected by the enclosed instrument. This led WMD to develop a custom hermetically sealed eSATA port that is used in this design. The four SSDs are easily removable without breaking the seal of the enclosure or disturbing the instrument environment.

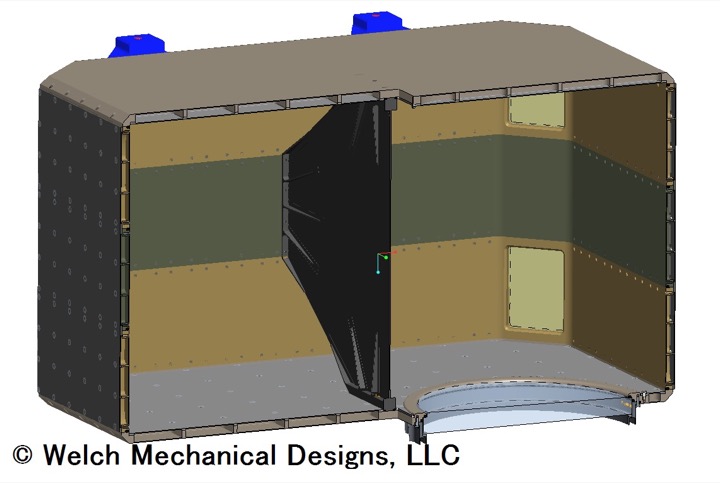

High Spectral Resolution LiDAR II (HSRL2) Environmental Enclosure

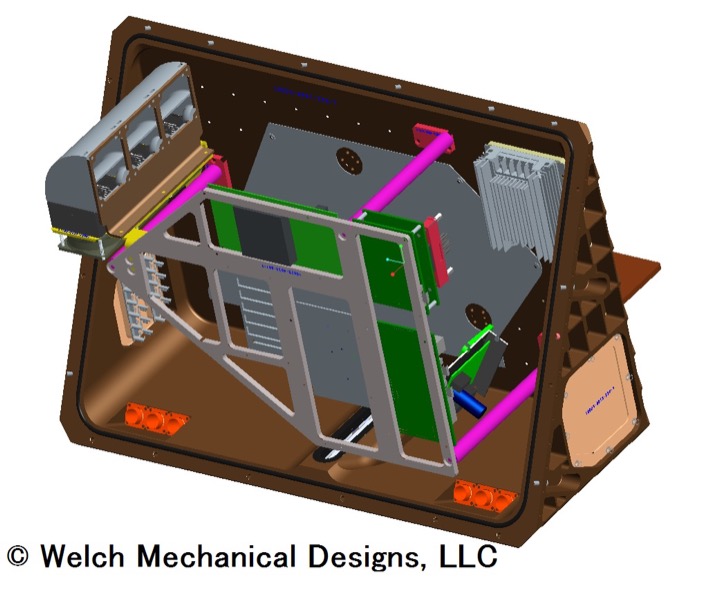

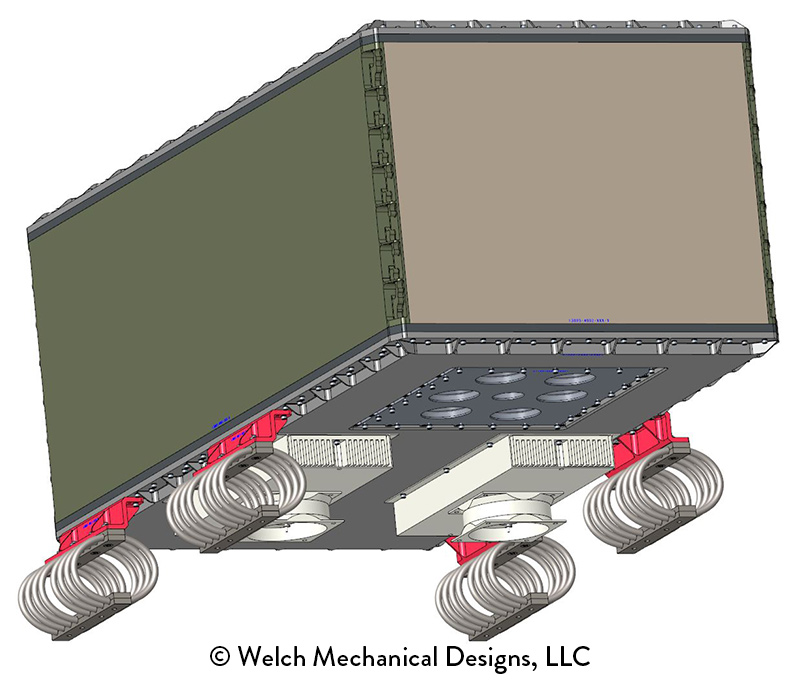

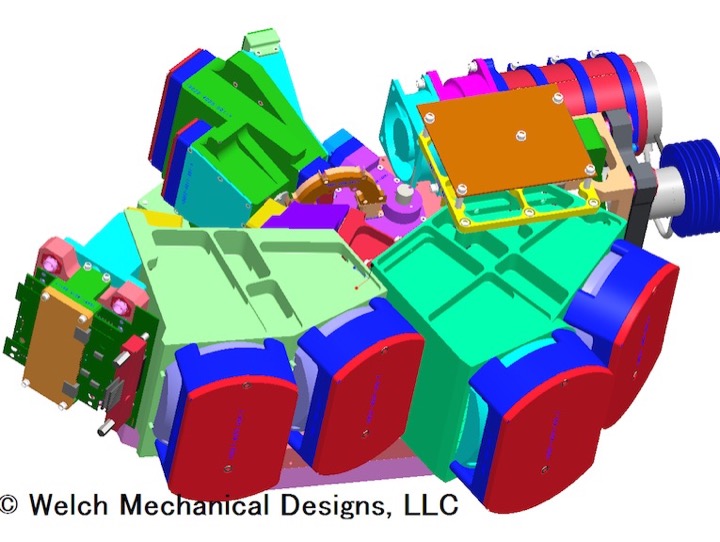

The HSRL2 Environmental Enclosure is a large enclosure created to house the HSRL2 instrument and its supporting components. This enclosure is designed to maintain pressure at altitude, and provide stable temperature and humidity control for the HSRL2 instrument. The enclosure, along with the HSRL2 instrument, is deployed in NASA's ER-2 high altitude research aircraft.

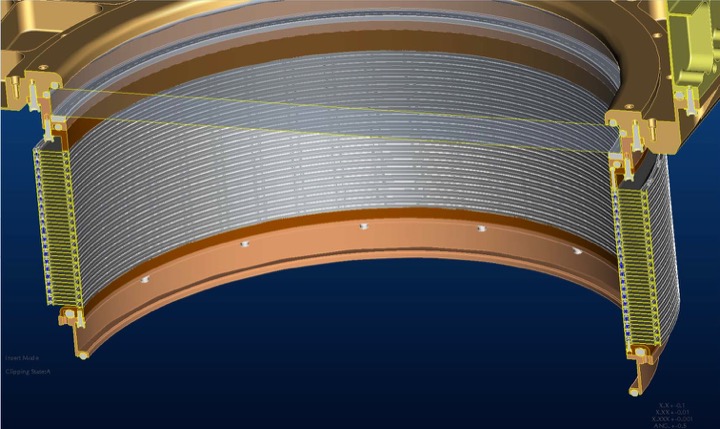

The HSRL2 enclosure is an adaptable design, having hundreds of tapped holes with helical coil inserts on both the inside and outside for mounting various components not included with the original configuration. The enclosure includes a specially designed electronics rack that houses various NASA instruments and a WMD-designed heating and cooling system. It also includes a 17-inch (43.2-cm) window and a unique bellows design.

The large size of the enclosure, 28 inches (71.1 cm) X 48 inches (121.9 cm) X 40 inches (101.6 cm) required extensive pocketing for weight reduction. To maintain strength, WMD devised a novel technique for creating a closed-cell structure rather than open pockets. This is significantly stronger for the same total mass. An extensive FEA was also performed to aid in reducing weight while maintaining structural integrity. As an example of the weight savings, the mass of the solid stock for the main enclosure was 5,250 lbs (2381.4 kg), and the final weight of the same finish-machined parts is just 230 lbs (104.3 kg).

All joints and openings are sealed using o-rings, and all assembly holes contain helical coil inserts. Leak tests performed by NASA showed acceptable leak rates even with eight o-rings missing! With the o-rings in place, they could not detect a reduction in internal pressure after a mission's full duration exposure to vacuum.

The HSRL2 enclosure has numerous exterior tapped holes with helical coil inserts. This allows the enclosure to be mounted in other types of aircraft with the addition of custom fit brackets.

Challenges:

One of the challenges of the HSRL2 inclosure was keeping the weight low on such a large enclosure. By employing extensive pocketing, multiple FEA iterations and high strength materials, WMD was able to meet this goal while still creating a structure that is very strong and maintains pressure at high altitudes.

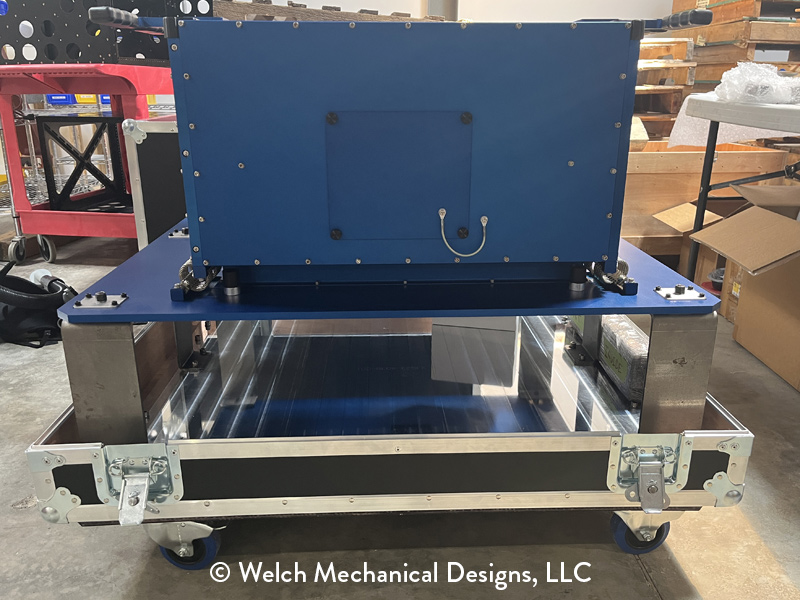

V-2048 Environmental Enclosure

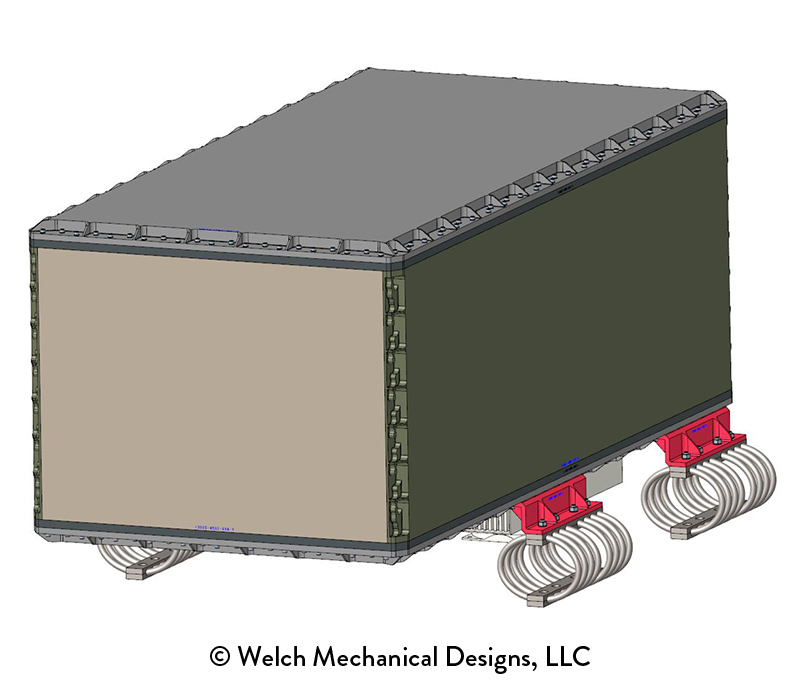

The V-2048 environmental enclosure is essentially a smaller version of the EMAS environmental enclosure, designed to house the V-2048 Instrument and be deployed in NASA's ER-2 high altitude research aircraft.

The V-2048 enclosure uses the same clam-shell design as EMAS to reduce the number of sealed joints, while still allowing good instrument access. It also contains a specially designed electronics support rack, one feed-through panel, a heating system for maintaining temperature at altitude, a unique oval-shaped window, and a single hard drive bay that can hold up to five 2.5-inch (63.5-mm) solid state drives.

Challenges:

WMD applied all the knowledge gained from the production of the EMAS enclosure to the V-2048 enclosure project. The biggest departure from the EMAS design is in the hard drive bay. Since V-2048 required a smaller enclosure, we did not have space for the two external drive bays that EMAS contained. WMD overcame this difficulty by creating a unique internal/external drive bay. A two-piece air-tight drive housing is mounted on the inside of the enclosure at a mating access port and sealed against the enclosure using an o-ring. The drive housing is fitted with four of the hermetically sealed eSATA ports that we developed for the EMAS version. Since the housing is sealed against the enclosure itself, it keeps the enclosure completely air-tight even with the drive bay's external cover panel removed. This allows easy access to the SSD's without compromising the interior environment.

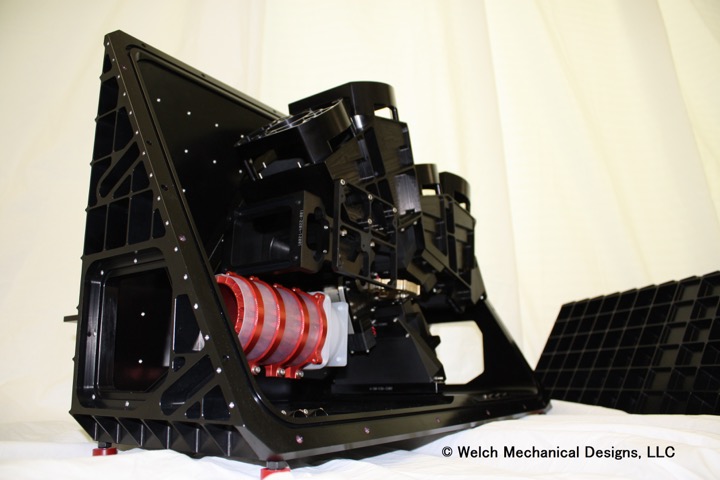

Airborne Lidar Enclosure

This enclosure protects a lidar receiver, transmitter and all sensor and support electronics from high altitude low pressure and low temperature environments during flight operations.

On the ground the system maintains temperature during ground testing. Overall size is 68 x 38.5 x 16.5 inches.

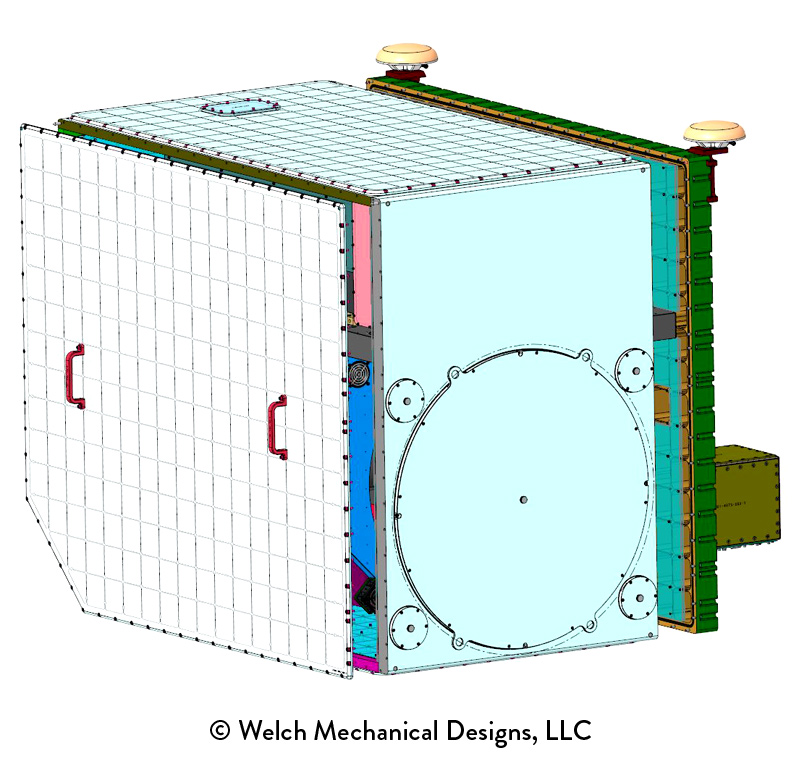

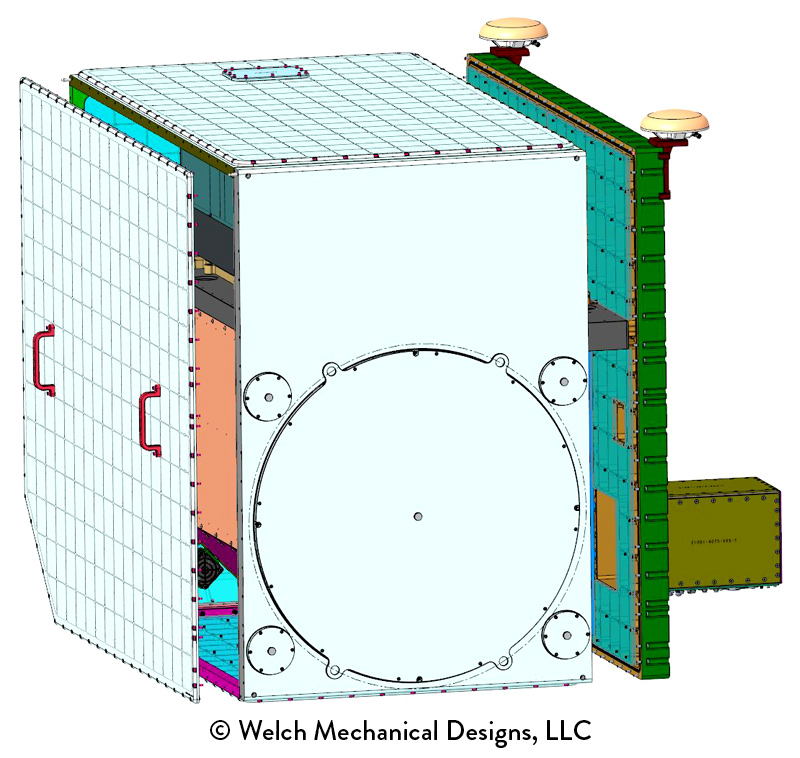

Concurrent Artificially-intelligent Spectrometry and Adaptive Lidar System (CASALS) Enclosure

The CASALS enclosure secures a compact lidar scanning system and hyperspectral imaging sensors in NASA's Beechcraft B200 Super King Air aircraft. This enclosure is composed of two sections, one for the lidar system and the other hanging below for the hyperspectral sensors and scene cameras. At 26" x 26" x 25" and 198lbs, featuring a standard 24"x24" breadboard this enclosure can accommodate a variety of science instruments. Custom high strength panel fasteners allows for quick access to the instrument without the risk of lost fasteners or reduced strength during installation. The strength of the enclosure was validated using extensive FEA analysis and review to be certified for aircraft use.

Challenges:

Multiple sensor apertures and a wide scanning lidar angular range required precision locating of the sensor to the aircraft window. WMD's extensive database of aircraft CAD models allowed us to have confidence the final assembly will properly locate the sensors so their apertures at the window are not obscured.

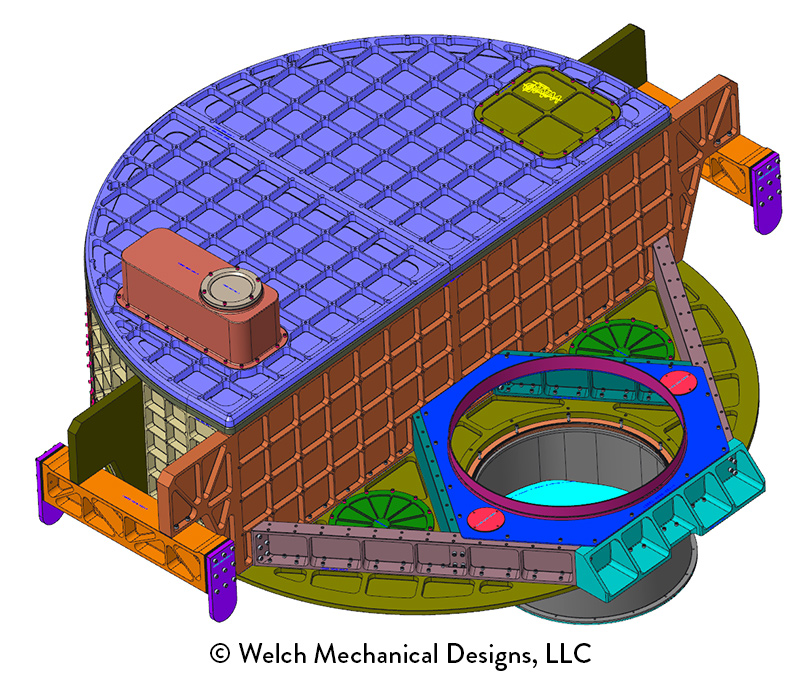

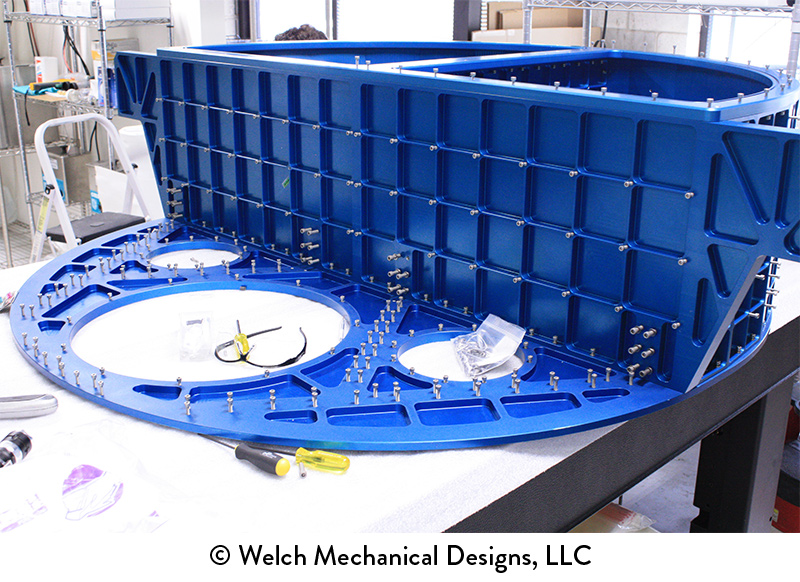

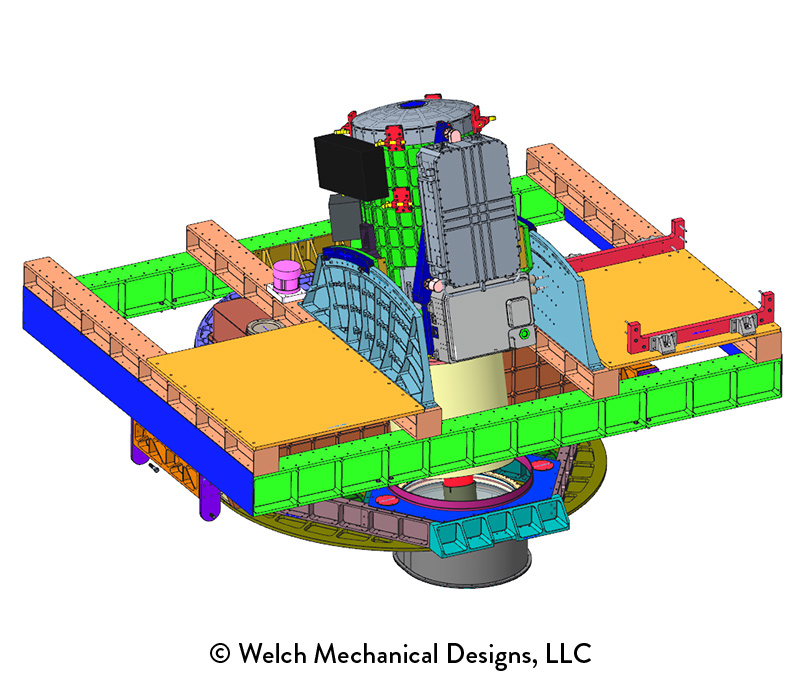

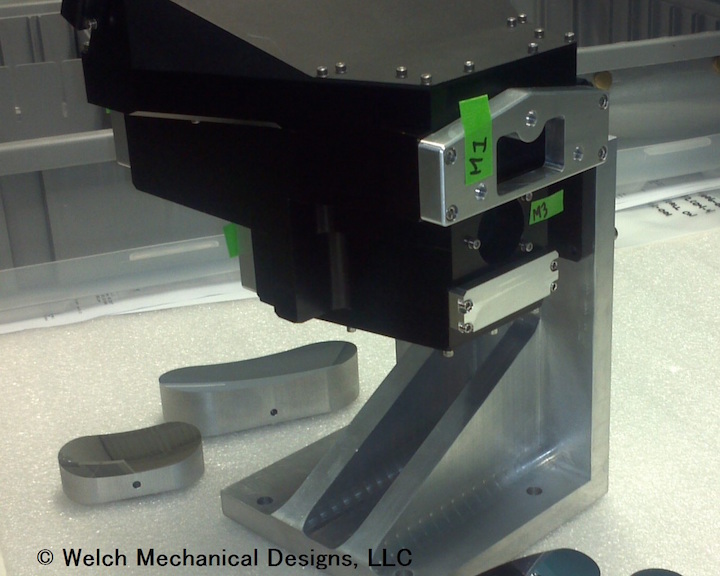

The North Atlantic Aerosols and Marine Ecosystems Study (NAAMES) Airborne System

The NAAMES airborne system is an aircraft enclosure designed to mount the HSRL lidar instrument, a scanning polarimeter and a UV to SWIR hyperspectral imaging camera. The enclosure supports investigations into processes controlling ocean system function, their influences on atmospheric aerosols and clouds and their implications for climate change.

To allow the HSRL instrument to be tilted and aimed at different angles, WMD designed a bracket to easily change the angle while mounted. The mounting bracket assembly features wire rope vibration isolators and quick release pins to angle the system to a desired position while keeping the instrument stable.

An interesting challenge for this project is interfacing to the 60" diameter port in the floor of the C-130 aircraft. This port was originally designed for an airborne laser testbed and decommissioned for NASA experiment use. WMD took extensive measurements of the aircraft interface which allowed drop in mounting of the enclosure and minimal match drilling. Our enclosure also sealed against the inflatable seal in the 60" diameter port without issue.