Enhanced MODIS Airborne Simulator (EMAS)

Enhanced MODIS Airborne Simulator (EMAS) :

The Enhanced MODIS Airborne Simulator (EMAS) is an airborne hyperspectral imager designed to be deployed in NASA's ER-2 high altitude research aircraft. It acquires high spatial and high spectral resolution imagery of cloud and surface features, aiding in assessing global climate change.

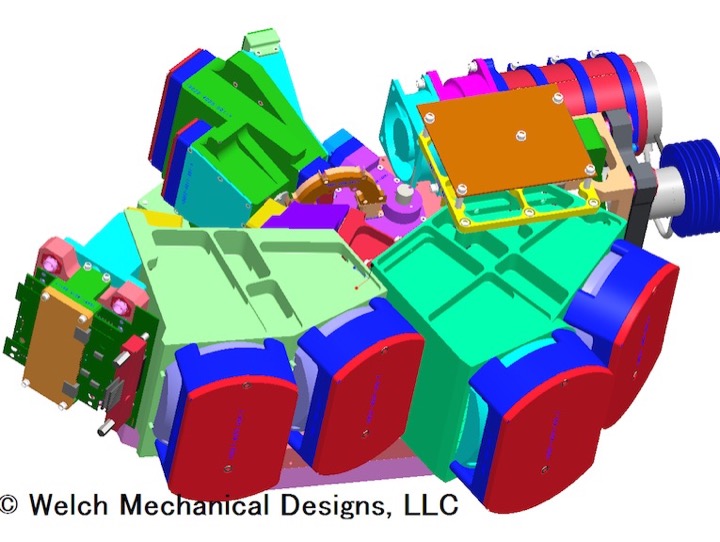

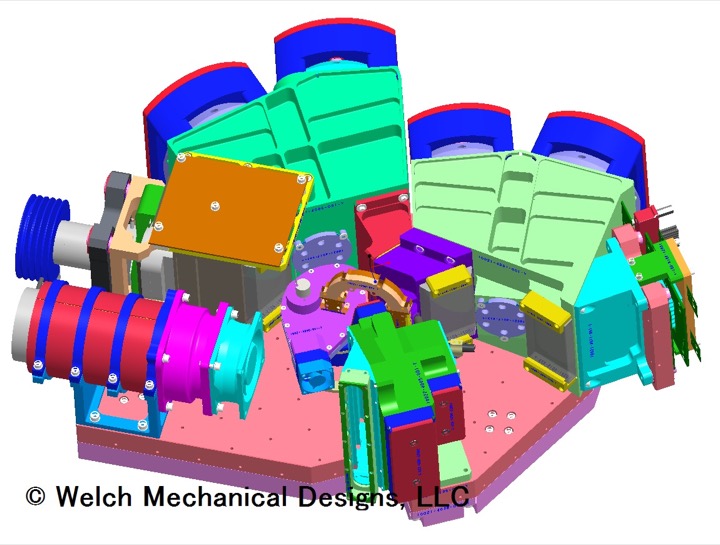

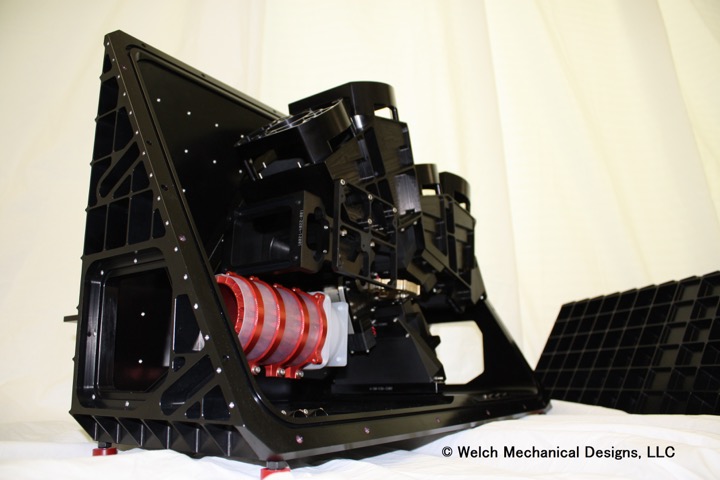

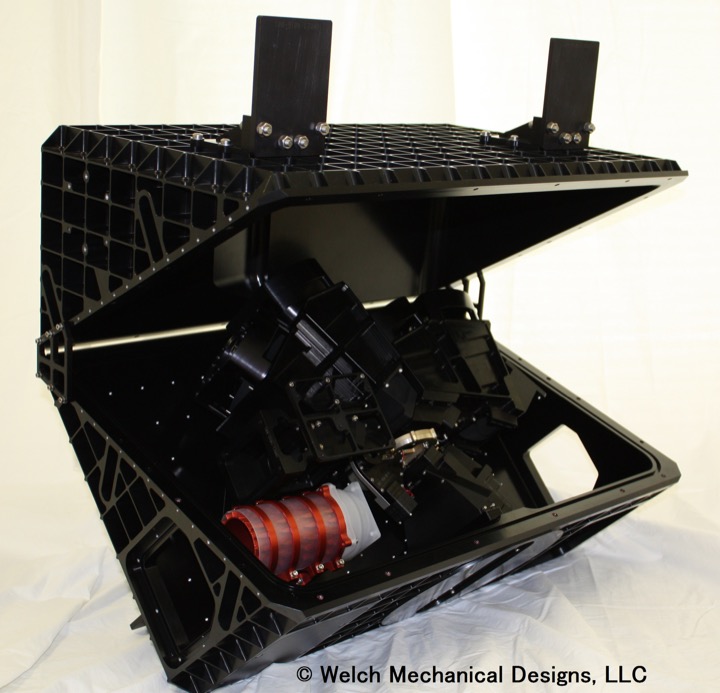

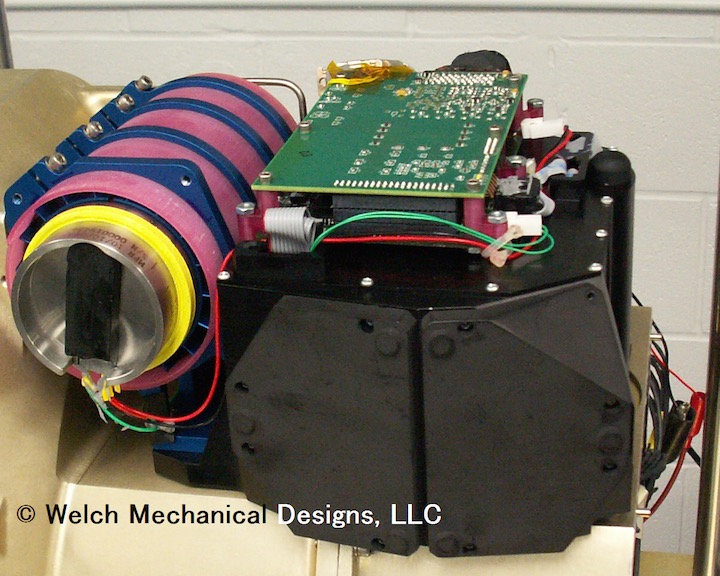

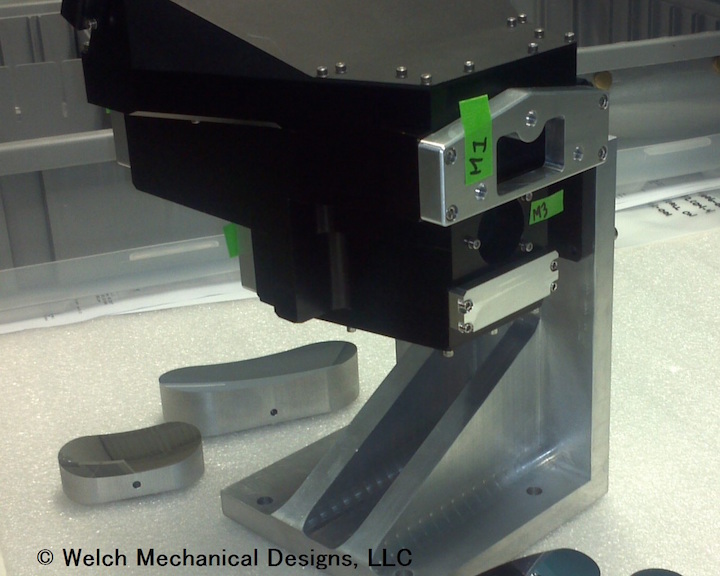

EMAS is a complex instrument consisting of an all-reflective telescope, two Offner spectrometers, two detectors, one detector cryocooler, a reference stability monitor (RSM) and a motorized turn mirror — all mounted to a two-piece, lightweight, bonded breadboard. The telescope is a four-mirror, all-reflective design with a 50-degree field of view and a glass slit that feeds light rays to both of the spectrometers. One spectrometer operates in the Visible and Near Infrared (VNIR) wavelengths and the other operates in the Short Wavelength Infrared (SWIR) spectrum.

Together, these cover a 380-nm to 2400-nm wavelength range. The RSM provides a stable light source emitting many wavelengths of light for in-flight spectral calibration. This light is directed into the spectrometers by means of a motorized turn mirror. When engaged, the turn mirror blocks incoming light from the telescope and only allows light from the RSM to enter the spectrometers. When disengaged, it allows only light from the telescope to enter the spectrometers.

The SWIR detector is actively cooled and the VNIR detector is passively cooled. The entire assembly is mounted into the EMAS Environmental Enclosure using three custom designed flexures to help isolate the instrument from thermal and mechanical induced distortions from the environment.

Challenges:

Fitting the large number of components into a predetermined space was a challenge as always. We also developed our first Wide Field Of View (FOV), all-reflective telescope for this project, snap-together optics, and grating technologies. Our Wide FOV telescopes can be seen here.

We learned a tremendous amount about manufacturing high-quality aluminum mirrors on this project. Through numerous experiments, WMD developed a new aluminum optic material that brings the typical diamond turned roughness of 60-80 Å RMS down to 25-40 Å RMS for optics up to 150 mm in diameter. This is achieved without nickel coating or post polishing. This process and material has been used on many subsequent projects, always with great success, and is a testament to our determination to continually develop new and better methods to improve our products.