Non-linear Optics Modules

Non-linear Optics Modules

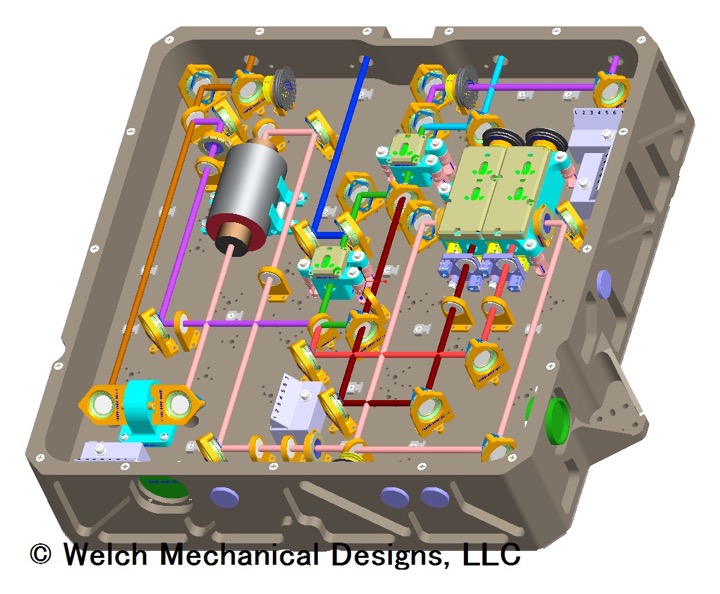

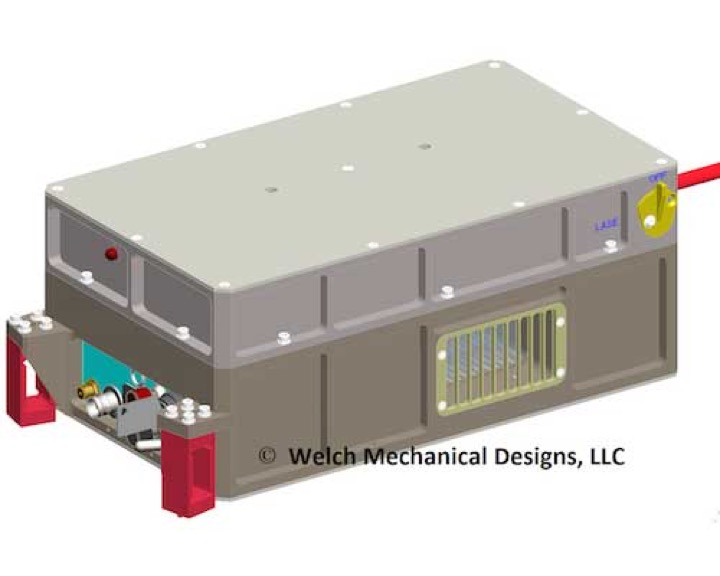

This project required WMD to design and manufacture a new Non-Linear Optics (NLO) Module for NASA's custom diode-pumped laser system in the HSRL2 instrument. The requirements were to improve mechanical stability, improve the design of the Optical Parametric Oscillators (OPO) and improve the thermal and mechanical design of the mixing crystals while preserving input/output locations, form factor and performance of their original NLO. In the lab, the new NLO has shown far better stability for longer periods of time than the original design.

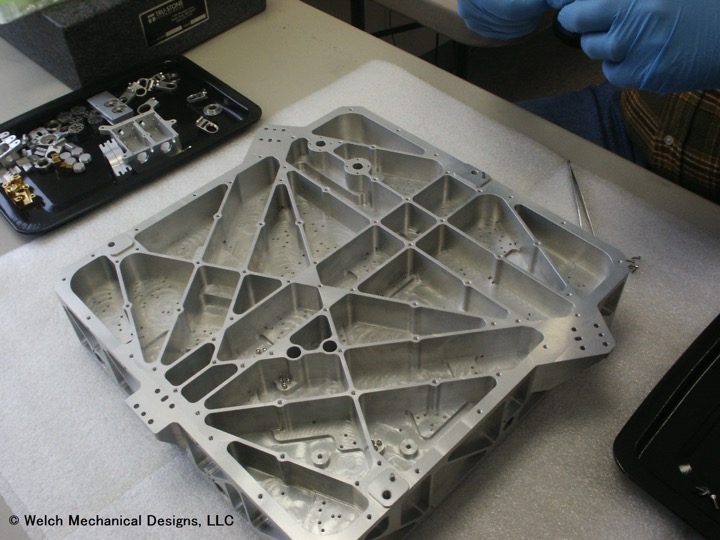

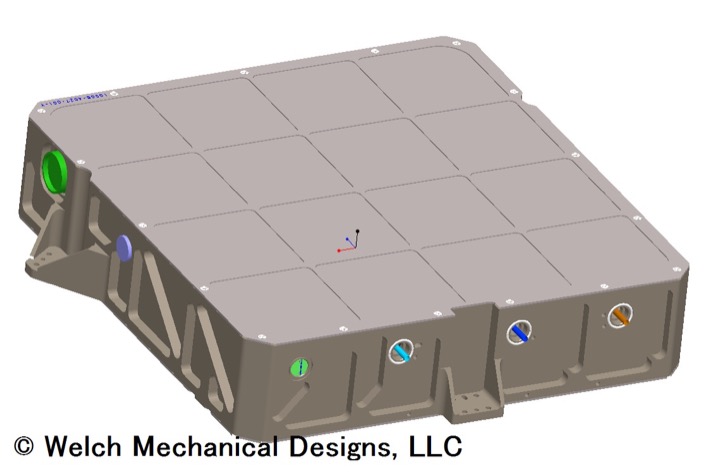

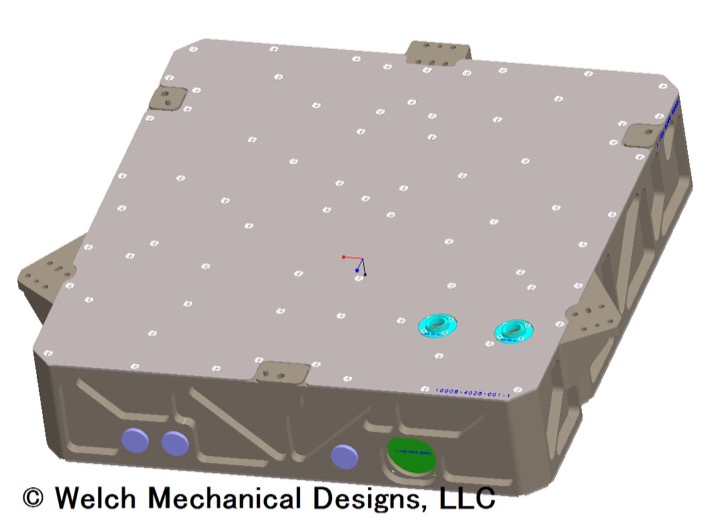

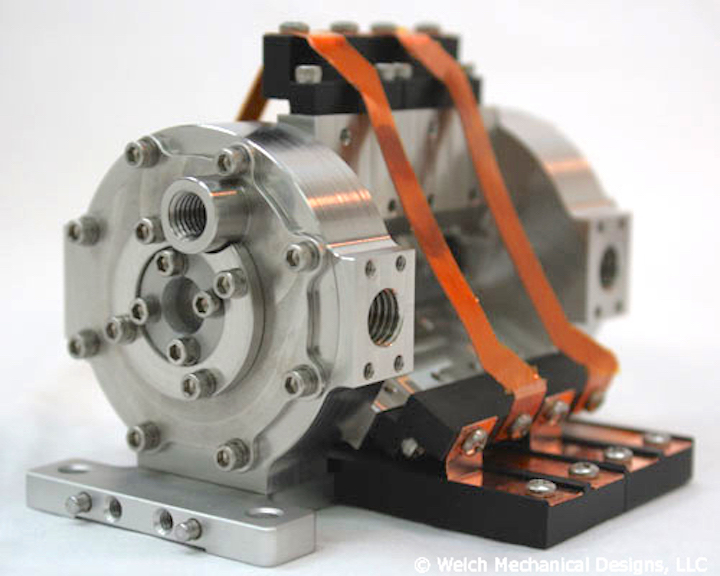

The NLO module converts the two incoming beams from the diode-pumped laser into four separate beams of different wavelengths, then feeds those four to the HSRL2 transmit optics system. NLO contains mechanical Risley pair optic mounts, tombstone optic mounts, mixing crystal modules with temperature control, a dual OPO module, custom beam dumps and heat sinks, electronics and dozens of flat optics for folding the design to fit into a small enclosure. The dual OPO module has temperature control, along with mechanical Risley optic mounts for steering incoming beams and custom differential screw adjusted optic mounts for steering outgoing beams. All these components are mounted in a lightweight housing that is designed to support the diode-pumped laser and provide for mounting into the HSRL2 transmitter assembly. The housing is designed using our closed-cell optical bench techniques for high stiffness and low mass, and mounting is accomplished via three custom designed flexures.

Challenges:

Due to the number of optics required by the design and NASA's request that we improve mechanical stability, WMD first reduced degrees of adjustment freedom wherever possible. This led to designing a housing that contained attachment points that would accept both adjustable and non-adjustable optic mounts, so the user can interchange mounts based on their adjustment requirements. This created the challenge of machining a housing with hundreds of small, precisely placed tapped holes and pin holes. Working closely with our machining staff, WMD was able to produce two of these housings without scrapping any setup pieces during manufacturing — a testament to our ability to get things right the first time.

2024 Upgrade

In continued support of this program, in 2024 WMD produced several upgrades for NLO.