ASCENDS CarbonHawk Experiment Simulator (ACES)

ASCENDS CarbonHawk Experiment Simulator (ACES) :

The Ascends CarbonHawk Experiment Simulator (ACES) is an airborne, multi-aperture CO2 sensing LIDAR system, designed to be deployed in the Global Hawk, UC-12 and DC-8 aircraft. The system measures column CO2 mixing ratios, discriminating cloud from aerosol, and provides ranging information from the laser transmitter system.

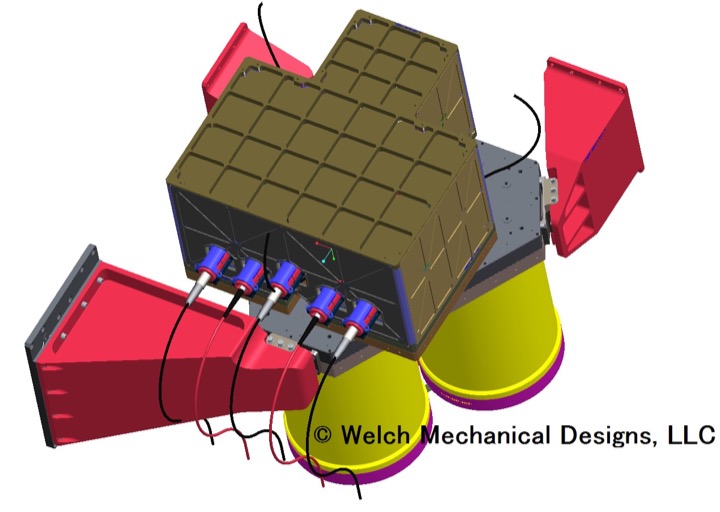

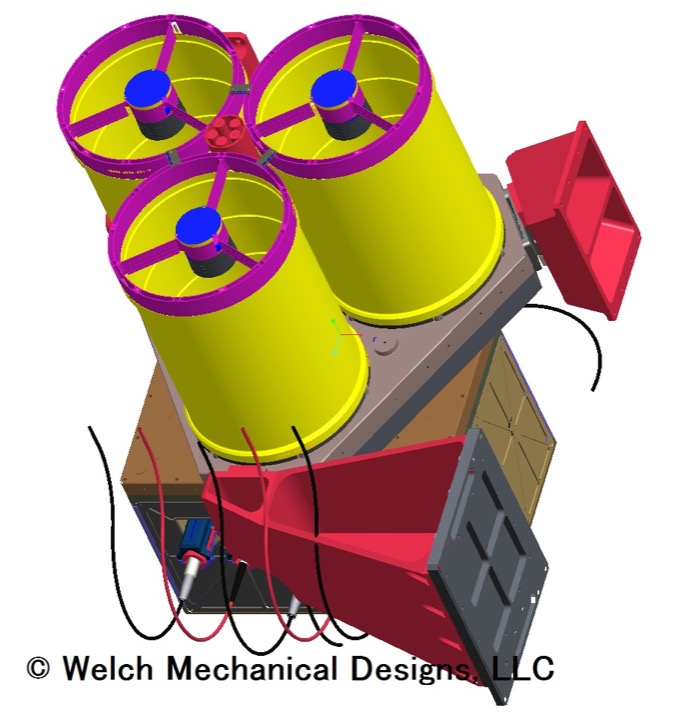

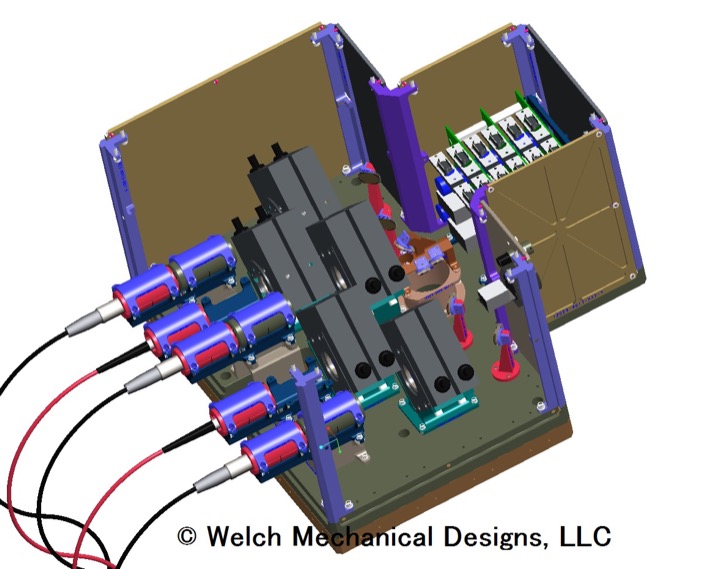

ACES consists of three 7-inch (178-mm) infrared telescopes mounted to a triangular lightweight bonded breadboard with a laser transmitter system mounted above. The laser transmitter is designed for five collimated fiber lasers with 10 motorized rotation stages for laser pointing control and has its own lightweight bonded breadboard. The transmitter system also houses the electronics for controlling the motorized stages and three custom designed beam expanders for the 1571-nm channels. The laser system transmits three beams at 1571-nm and two beams at 1260-nm. The reflected light is collected by the three 7-inch (178-mm) telescopes, and then that light is fed to the detector via fiber optic cables.

The entire system is mounted in a sealed enclosure using three custom designed hollow mounting brackets and Titanium flexures mounted to the edge of the breadboard. The telescope/transmitter is easily removed and replaced in the enclosure with this mounting system.

Challenges:

The biggest challenge in ACES was the laser transmitter. With five laser inputs, three beam expanders, ten motorized rotation stages, electronics and multiple turning mirrors, it was a challenge to maintain access to the fiber connectors for the telescopes. All of the beams had to be collected near the center of the three telescopes to be transmitted through to the window in the bottom of the aircraft while not interfering with one another. The lasers also had to be enclosed for eye protection.

These challenges were solved by creative alignment of the ten rotation stages which were mounted in two overlapping, two-tiered rows with just enough room for the rear beams to pass underneath the forward stages. The beams were then turned to a unique five-mirror mount to pass them through the breadboards and out of the aircraft. Above the breadboard, the lasers, electronics and other components are encased in a post and panel enclosure, and below the breadboard they are enclosed in a multi-part tube. With the addition of a notch in the transmitter breadboard and a unique mount for one of the laser collimators, access to the telescope fibers was maintained.

Another challenge was the bore-sighting of the three mounted telescopes. The system spec was 25 urad, but we achieved 3.92 urad coalignment of the three 7-inch telescopes.

The bonded breadboard techniques we learned from this project have already been put to good use on other projects, as have the custom beam expander designs.