2-Micron Laser

2-Micron Laser :

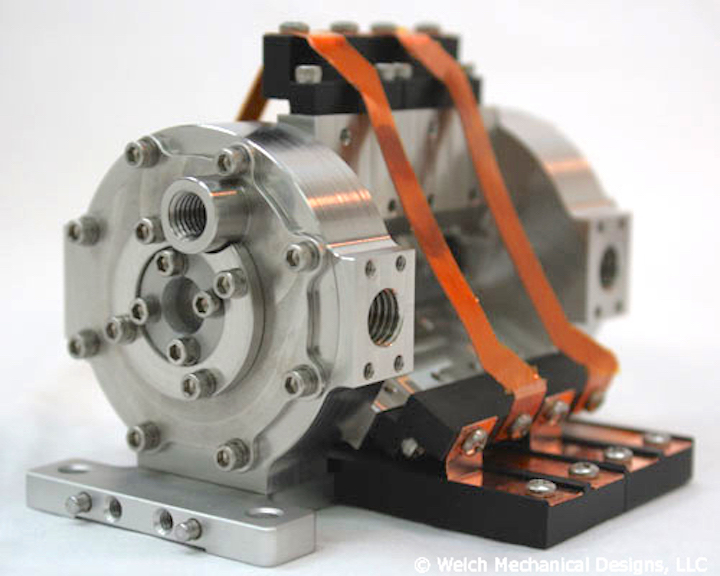

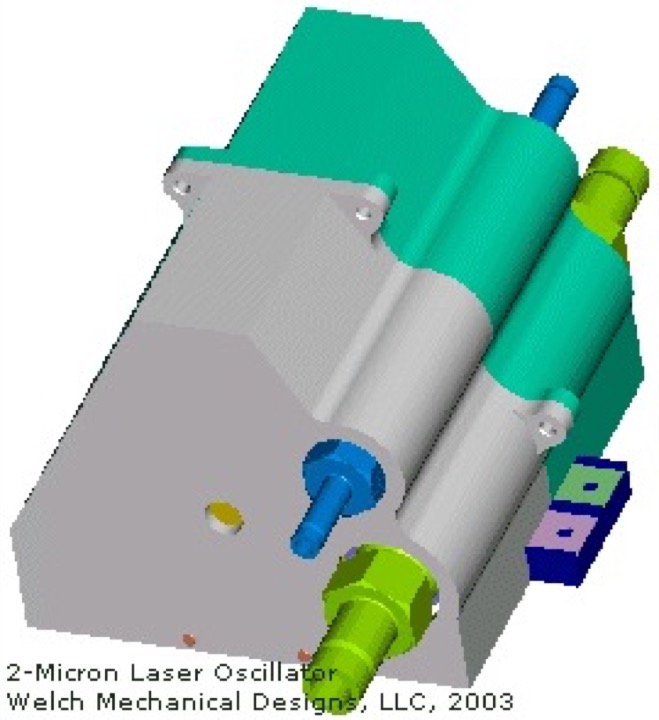

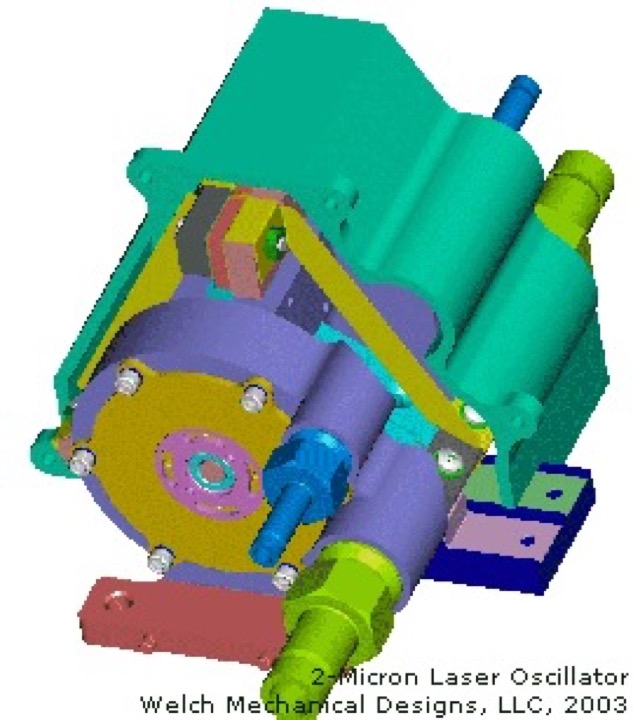

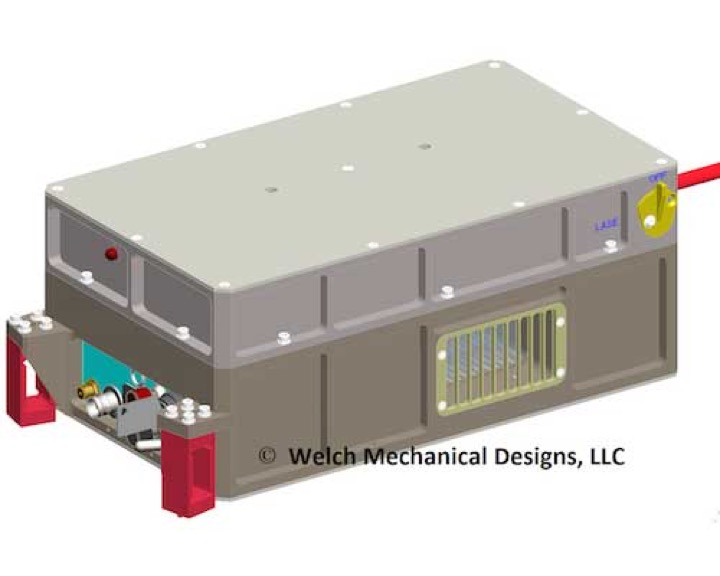

Welch Mechanical Designs (WMD) was brought into a NASA diode-pumped laser development team to provide mechanical design and manufacturing consulting. The NASA team was researching methods to build ruggedized diode-pumped lasers suitable for deployment in the field. The research team had built their own oscillator that pumped a LuLF crystal at 790 nm to produce 2-micron wavelength laser light at a repetition rate of 10 Hz. WMD's primary goal was to improve the liquid cooling efficiency that would, in turn, increase the lifetime of the pump diodes.

Since the laser was water cooled, a major effort of the design required optimizing the cooling efficiency of the water channels. The original design made the coolant flow serially through the laser diode mounts, but the plumbing lines used for this method required too much space. The new design used a built-in manifold to split the single incoming flow into three parallel flows for the three banks of diodes. This reduced the packaging size of the oscillator significantly. However, it reduced the relative flow rate for each diode compared to the serial design. WMD coordinated fluid flow analyses to improve the heat transfer coefficient. The final design increased the flow rate enough to achieve turbulent flow which increased the heat transfer coefficient. This allowed the NASA team to use their current chiller with a limited maximum flow capacity.

WMD also coordinated efforts to implement an optical technique to improve the efficiency of the design. We created coating masks and coordinated the efforts of both an optics manufacturer and an optics coater to make these components.